Unlock New Business Opportunities with COVNA in Guangzhou!

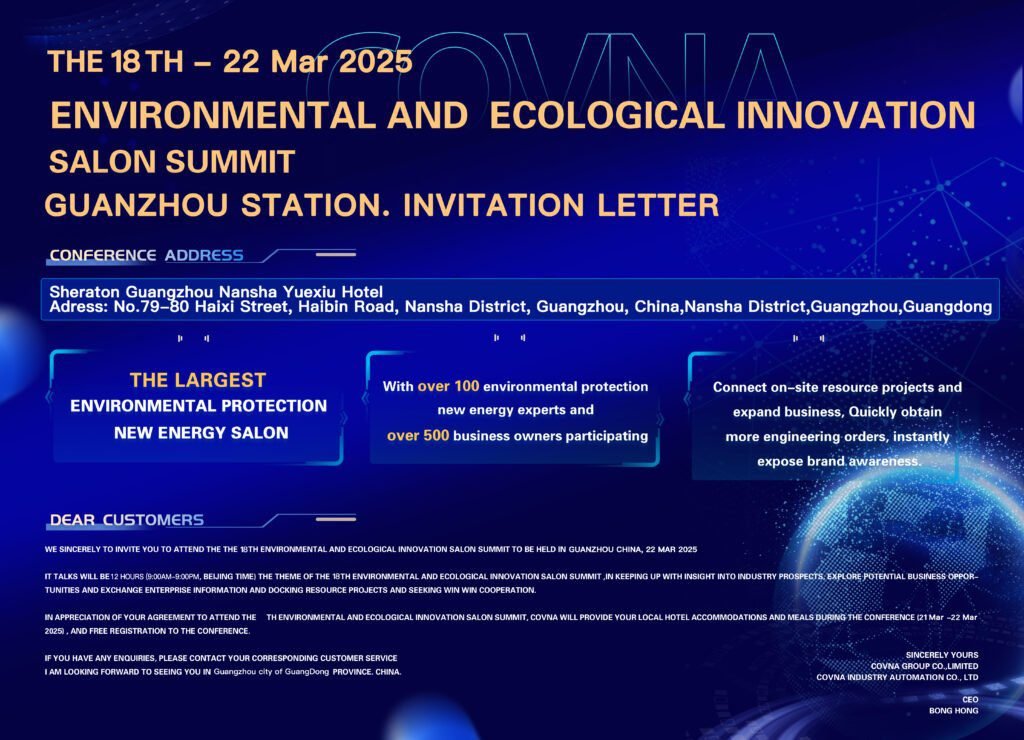

Are you looking to expand your global business network, gain industry insights, and explore groundbreaking innovations in environmental technology? If so, mark your calendar for March 22, 2025, and join us at the 18th COVNA Environmental Innovation Salon & International Summit in Guangzhou, China!

This prestigious event, hosted by COVNA, brings together global industry leaders, entrepreneurs, and experts to discuss the latest developments, explore business collaborations, and create new opportunities in the industrial and environmental sectors.

Why Should You Attend?

1. Gain Industry Insights and Stay Ahead of the Competition

The COVNA Innovation Summit is designed to keep businesses at the forefront of global industry trends. With in-depth discussions led by renowned experts, you will gain valuable insights into market developments, technological advancements, and sustainable solutions that can propel your business forward.

2. Connect with Global Industry Leaders

Building strong international partnerships is the key to expanding overseas markets. At this summit, you’ll have the chance to network with decision-makers, business owners, and industry professionals from around the world. This is your opportunity to establish strategic alliances and explore new markets for your business.

3. Explore Cutting-Edge Environmental Innovations

With sustainability at the core of modern business, our event highlights the latest innovations in industrial and environmental solutions. Engage in discussions on eco-friendly technologies, smart industrial applications, and green energy solutions that are shaping the future.

4. Exclusive Benefits for Attendees

As a valued guest, COVNA will provide complimentary hotel accommodations and meals during the conference from March 21-22, 2025. Additionally, all registered attendees will receive free entry to the summit, ensuring an enjoyable and productive experience.

What to Expect at the 18th COVNA Environmental Innovation Summit?

- Engaging Panel Discussions – Listen to industry pioneers discuss emerging trends, challenges, and opportunities.

- Networking Sessions – Connect with potential business partners, clients, and industry experts.

- Exclusive Business Matchmaking – Find partners that align with your business goals.

- Live Product Demonstrations – Experience innovative industrial and environmental solutions firsthand.

Join Us in Guangzhou – Reserve Your Spot Today!

Would you like to expand your business globally and explore new collaboration opportunities? Don’t miss out on this exclusive event!

Are you ready to take your business to the next level?

📌 Register now and secure your place at the 18th COVNA Environmental Innovation Salon & International Summit!

📅 Event Date: March 22, 2025

📍 Location: Guangzhou, China

🎟️ Free Registration & Complimentary Hotel Accommodation

📩 Contact us now to confirm your attendance!

Don’t hesitate to reach out if you have any questions. We look forward to welcoming you to Guangzhou and creating win-win business opportunities together!

What is an Idle Air Control (IAC) Valve?2026-01-22/0 Comments

What is an Idle Air Control (IAC) Valve?2026-01-22/0 Comments