Knowledge About Valves

Recent Posts

-

What is an Idle Air Control (IAC) Valve?2026-01-22/0 Comments

-

-

-

-

Pneumatic ball valves, as key components in industrial automation control, are widely used in water treatment, chemical, food, pharmaceutical, and other fields. However, many engineers tend to overlook key factors during the selection process, leading to reduced system efficiency or even operational failures. This article will address the three most common mistakes in pneumatic ball valve selection and provide practical advice to help you make an accurate choice.

Mistake 1: Ignoring Media Characteristics

Many people focus solely on caliber and pressure when selecting a pneumatic ball valve, overlooking the media's corrosiveness, viscosity, or particulate content.

Consequences of this error: Mismatched valve body materials can lead to corrosion, blockage, or seal failure.

Solution: Determine the media type before selecting a valve and select the appropriate valve body material (such as stainless steel, PVC, or PTFE seals).

Covna recommends: For corrosive media, prioritize 316 stainless steel ball valves with corrosion-resistant seals.

Mistake 2: Ignoring Actuator Parameters

The actuator for a pneumatic ball valve needs to be matched to the operating pressure, frequency of operation, and control method.

Consequences of Errors: Insufficient or excessive actuator thrust, resulting in sluggish operation or damage.

Solution: Select an appropriate double-acting or single-acting pneumatic actuator based on the system air pressure and valve torque requirements.

Covna Recommendation: Use the Covna Torque Calculator to quickly match actuator models to avoid overload or underactuation.

Mistake 3: Ignoring Control Methods and Signal Feedback

In automation systems, the need for solenoid valve control, position feedback, limit switches, etc. is a key consideration when selecting an actuator.

Consequences of Errors: The system cannot achieve remote control or status monitoring, impacting overall operational efficiency.

Solution: Clarify control requirements and select pneumatic ball valves with solenoid valves, feedback sensors, or intelligent positioners.

Covna Recommendation: For PLC control systems, pneumatic ball valves with feedback sensors and NAMUR interfaces are recommended for precise feedback.

Covna Pneumatic Ball Valve Solutions

Covna offers a variety of pneumatic ball valves, supporting customized materials, interfaces, and control accessories to meet diverse operating requirements. Whether it's high-corrosion, high-frequency operation, or intelligent control systems, we can provide you with professional selection support.

View Covna's pneumatic ball valve products: https://www.china-covna.com/covna_product_menu/pneumatic_valve/

Still struggling to select a pneumatic ball valve? Submit your application requirements and we'll customize a solution for you within 24 hours!

Solution: Select an appropriate double-acting or single-acting pneumatic actuator based on the system air pressure and valve torque requirements.

Solution: Clarify control requirements and select pneumatic ball valves with solenoid valves, feedback sensors, or intelligent positioners.

In industrial automation systems, electric and pneumatic valves are widely used actuators for controlling flow remotely. While they share similar control functions, their operating principles, performance characteristics, and suitable applications differ significantly.

This guide walks you through the core distinctions, helping you make confident choices for your projects.

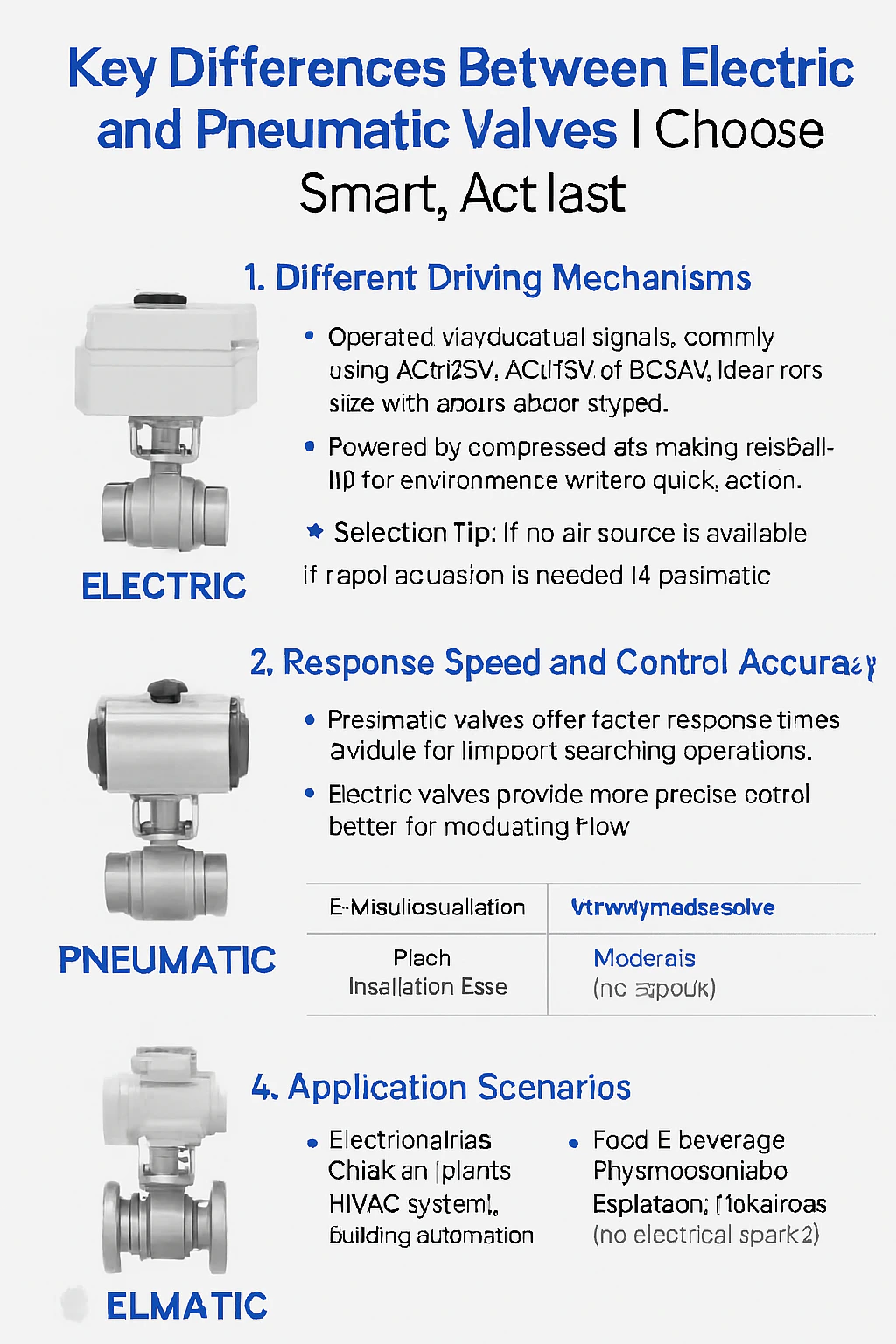

Different Driving Mechanisms

Electric Valve: Operated via electrical signals, commonly using AC220V, AC110V, or DC24V. Ideal for areas with stable power supply.

Pneumatic Valve: Powered by compressed air, making it suitable for environments where quick action and existing air systems are common.

Selection Tip: If no air source is available, go electric. If rapid actuation is needed, pneumatic is your friend.

Response Speed and Control Accuracy

Pneumatic valves offer faster response times, perfect for frequent switching operations

Maintenance and Cost Overview

| Feature | Electric Valve | Pneumatic Valve |

|---|---|---|

| Installation Ease | High (no air supply) | Moderate (requires air) |

| Maintenance Level | Low | Higher (air system upkeep) |

| Initial Investment | Higher | Moderate |

| Operating Costs | Lower (electric use) | Higher (air compression) |

Application Scenarios

Electric Valves: Chemical plants, HVAC systems, building automation.

Pneumatic Valves: Food & beverage, pharmaceuticals, explosion-risk areas (no electrical sparks).

Safety Note: For hazardous environments, pneumatic valves reduce risk of spark-related incidents.

How Covna Supports Your Selection

Covna offers a wide range of electric and pneumatic valves, including ball, butterfly, and gate types—with custom options to meet your specific needs.

COVNA's new VX31 3-way brass solenoid valve combines smart design and rugged materials, making it an ideal upgrade for multi-channel fluid systems. Whether you want to divert, switch or mix water, oil or gas, the VX31 provides stable, energy-efficient control with long-lasting durability and outstanding performance.

Product Features

- High-precision three-way structure VX31 adopts equal percentage three-way design, which can flexibly realize fluid distribution and switching, support A→B/C and B→A/C two working modes, and meet the needs of multiple working conditions.

- High-quality brass material The valve body is made of C37700 brass, which is precision cast and processed, with excellent corrosion resistance and mechanical strength to ensure long-term stable operation.

- Quick response The coil drive can operate normally with ±10% voltage fluctuation, the opening time is less than 15ms, and the closing time is less than 20ms, ensuring instantaneous and accurate fluid switching.

- Wide pressure compatibility Supports 12VDC, 24VDC, 24VAC, 110VAC, 220VAC and multiple voltage specifications, which can be flexibly selected according to system requirements.

- Strong pressure bearing capacity The maximum working pressure can reach 1.0MPa (10bar), and the minimum starting pressure is 0bar, which can be opened immediately to meet various working conditions from low pressure to medium pressure.

- Ultra-long service life The coil and valve core are optimized and designed to have a service life of more than 500,000 times, low maintenance cost and high reliability.

- Multiple interface forms Provide G (BSPP), NPT, internal thread, flange and other connection methods for quick integration into existing systems.

Technical Parameters

| Parameter | Specification Range |

|---|---|

| Body Material | C37700 brass |

| Port Size Range | 1/4", 3/8", 1/2", 3/4", 1" |

| Pressure Range | 0 – 1.0 MPa (0–10 bar) |

| Temperature Range | –10 °C to +80 °C |

| Applicable Media | Water, air, oil, gas, light chemical media, etc. |

| Voltage Options | DC 12 V, DC 24 V, AC 24 V, AC 110 V, AC 220 V |

| Protection Level | IP65 |

| Response Time | Opening < 15 ms; Closing < 20 ms |

| Service Life | ≥ 500,000 cycles |

| Connection Types | G (BSPP), NPT, flange, etc. |

Why choose COVNA?

- Professional manufacturing: COVNA has been focusing on the research and development and production of solenoid valves since 2000, and its products have passed ISO9001, TÜV, SGS, RoHS and other certifications.

- Flexible customization: No minimum order quantity limit, support OEM/ODM, and quickly debug according to customer needs.

- Technical support: From selection to installation, debugging, and after-sales, one-stop service ensures that you have no worries.

- Cost-effectiveness: Direct factory quotation, quality comparison is more price competitive.

Consult now to start a new era of automated fluid control! We look forward to working with you to create efficient and reliable intelligent fluid solutions!