COVNA Products

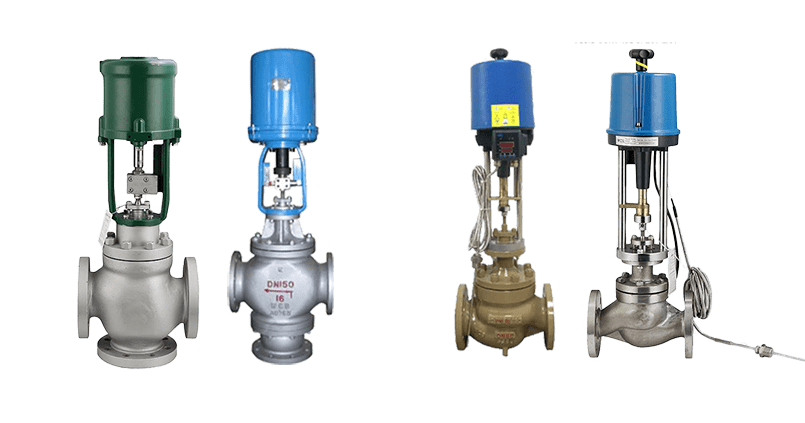

COVNA 3 Way Mixing Diverting Electric Globe Control Valve

3 way electric control valve has two action types: electric mixing(converging) control valve and electric diverting(diverging) control valve.The 3 way electric control valve is composed of PSL series and 3810 series linear electric actuator and 3-way valve body.The electric actuator is an electronic integrated structure with a servo amplifier. The input control signal (4-20mADC or 1-5VDC) and the power supply can control the valve opening to achieve to control the parameters of pressure, flow, liquid level and temperature. The electric 3-way mixing control valve is mainly used for mixing two fluids into a third fluid; the 3 way diverging electric control valve is mainly used for dividing one fluid into two fluids.

Model: Electric control valve

Size Range: 1'' to 12''

Pressure Range: 1.6 to 6.4MPa

Material: Stainless Steel, WCB

Actuator Parameter:

| Model | Rated output power | Speed of mm/s | Technical parameters | ||||

| PSL | 361L | PSL | 361L | PSL | 361L | PSL | 361L |

| 201 | 361LSA-08 | 1000 | 800 800 | 0.25 | 4.2 4.2 | Power supply; AC220V 50HZ Input signal: DC4-20mA DC1-5V (shielding line signal line) output signal: DC4-20mA protection grade: IP67 With the handwheel |

Power supply: AC220V 50Hz Input signal: DC4-20mA DC1-5V (shielding line signal line): DC4~20mA output signal Protection grade: IP65 Explosion proof mark Exdll With handle |

| 361LXA-08 | |||||||

| 202 | 361LSA-20 | 2000 | 2000 2000 | 0.5 | 2.1 2.1 | ||

| 361LXA-20 | |||||||

| 204 | 361LSA-30 | 4500 | 3000 3000 | 0.5 | 3.5 3.5 | ||

| 361LXA-30 | |||||||

| 208 | 361LSA-50 | 8000 | 5000 5000 | 1 | 1.7 1.7 | ||

| 361LXA-50 | |||||||

| 312 | 361LSC-65 | 12000 | 6500 | 0.6 | 2.8 | ||

| 320 | 361LSC-99 | 20000 | 10000 | 1 | 2 | ||

Valve Parameter:

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| Seat diameter mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| Rated KV | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 | 800 | 1280 |

| Nominal pressure (MPa) | 1.6,2.5,4.0,6.4 | |||||||||||

| Trip(mm) | 16 | 25 | 40 | 60 | 100 | |||||||

| With electric actuator model | 361LSA-20 | 361LSB-30 | 361LSB-50 | 361LSB-65 | 361LSB-99 | |||||||

| Input signal | 4-20mADC,1-5VDC | |||||||||||

| Power Supply | AC220V 50HZ | |||||||||||

| The inherent flow characteristics | Linear, equal percentage, quick opening | |||||||||||

| The inherent modulation ratio | 30:01:00 | |||||||||||

| The inherent modulation ratio | IV | |||||||||||

| Flange size | According to JB/79.1 (2) -94, HG20592-97, GB, ANSI, JIS, DIN and other standards | |||||||||||

| Body material | WCB, 304, 316, WC6, nickel, titanium, Hastelloy, Monel etc. | |||||||||||

| Valve material | 304, 316, 420, nickel, titanium, Hastelloy, Monel etc. | |||||||||||

| Working temperature ℃ | -40~230 | |||||||||||

| Series type | At room temperature, medium temperature type, bellows seal type | |||||||||||

The performance index:

| Project | Index value | ||

| The basic error % | With 361L±2.5;;With PSL±1.0 | ||

| Differential% | With 361L±2.0;;With PSL 1.0 | ||

| The dead zone % | With 361L±3.0; With PSL 1.0 | ||

| Always point bias % | Electric drive | The starting point | ±2.5 |

| Finish | ±2.5 | ||

| Power off | The starting point | ±2.5 | |

| Finish | ±2.5 | ||

| Adjustable range | 50: 1 | ||

| Rated stroke deviation% | 2.5 | ||

| Leakage | According to JB/T7387-94 IV less than the valve rated capacity of X10 -4 | ||

Dimensions and weight:

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L | PN16 | 185 | 200 | 220 | 250 | 275 | 300 | 350 | 410 | 450 | 550 | 670 | 770 |

| PN40 | 190 | 210 | 230 | 255 | 285 | 310 | 355 | 425 | 460 | 560 | 740 | 803 | |

| PN64 | 200 | 200 | 240 | 265 | 295 | 320 | 370 | 440 | 475 | 570 | 752 | 819 | |

| H1 | 135 | 152 | 165 | 180 | 200 | 220 | 222 | 265 | 322 | 362 | 508 | 563 | |

| A | 225 | 310 | |||||||||||

| H Normal atmospheric temperature | 555 | 561 | 660 | 675 | 863 | 868 | 872 | 905 | 920 | 950 | 1203 | 1265 | |

| H Medium temperature | 707 | 709 | 812 | 827 | 1027 | 1032 | 1036 | 1120 | 1135 | 1165 | 1485 | 1557 | |

| Weight (PN64 Normal atmospheric temperature) |

50 | 55 | 70 | 78 | 110 | 120 | 150 | 180 | 310 | 410 | 650 | 810 | |

Types of Electric Control Valves:

The actuator on my automated valve operates, but the valve won’t turn. Why?

Most likely the valve stem or actuator coupling is broken.

Why doesn’t my valve open or close completely when the actuator operates it?

The electric actuator limit switches or the pneumatic actuator position stops are not correctly adjusted.

When I energize the solenoid on my pneumatic actuated valve, the valve won’t turn. How come?

Probably because there is no air pressure to the solenoid or dirt has jammed it. Also, debris might be trapped inside the valve. Or, the air pressure is not sufficient to operate the actuator. Remember: measure air pressure at the actuator, not at the compressor.

Can I buy an actuator from one manufacturer and mount it to a valve from another manufacturer?

Maybe. First, be sure that the actuator torque output is sufficient to turn the valve reliably. Second, you will have to fabricate a custom mounting bracket and coupling to connect the actuator to the valve.

What happens if I lose power to my electric actuator in the middle of an actuation cycle?

The valve will stop somewhere between full open and close. When power is reapplied to the original circuit, the actuator will complete the cycle.

I ordered a fail open pneumatic actuated valve by mistake. I needed a fail closed one. What can I do?

To make the change just remove the actuator from the valve and turn it, or the valve stem, 90 degrees and remount the actuator.

I’ve installed my automated valve in the line, but now I don’t know if the valve is in the open or closed position. How can I find out?

Remove the actuator from the valve and check the valve stem. Most ball valves have stem flats at right angles to the flow when the valve is in the off position. On butterfly valves check the stem flow arrow marking.

Do I have to have the solenoid valve that controls the air supply to my pneumatic actuator mounted right on the actuator?

Remove the actuator from the valve and check the valve stem. Most ball valves have stem flats at right angles to the flow when the valve is in the off position. On butterfly valves check the stem flow arrow marking.

How do I wire up my electric actuator?

Check the electric wiring schematic that came with the actuator for the correct hookup. Sometimes a copy is inside the actuator cover. If it is missing, don’t guess about the connections. Call the manufacturer for a schematic.

I’ve just installed an electric actuated valve and when I power it, it turns the valve 360 degrees and won’t shut off. What’s wrong?

The actuator is wired incorrectly (check the schematic accompanying the actuator), or the external control switch is not the correct type for the actuator.

My electric actuators cycle time is way too fast, can I slow it down?

Not unless you bought it with an optional speed control.

I just replaced a solenoid valve with an electric actuated valve and it won’t work. Why?

Actuators and solenoid valves require different types of electrical control switches. SPDT for actuators, SPST for solenoids. Check the actuator wiring schematic for the correct wiring and switch type.