Knowledge About Valves

Recent Posts

-

What is an Idle Air Control (IAC) Valve?2026-01-22/0 Comments

What is an Idle Air Control (IAC) Valve?2026-01-22/0 Comments -

-

-

-

Understanding how does a check valve work is key to appreciating its role in fluid systems. A check valve is designed to allow flow in one direction while effectively preventing reverse flow. This simple yet efficient mechanism protects equipment and systems from damage due to backflow.

At its core, a check valve consists of a movable component—such as a ball, disc, or poppet—that responds to pressure differences. When fluid moves in the intended direction, the pressure pushes the part open, allowing the fluid to pass. If the flow reverses, the component shifts into a closed position, stopping any backflow. COVNA engineers design these valves with precision, ensuring durability and reliable performance under various operating conditions.

By reducing turbulence and preventing unwanted fluid movement, check valves contribute to improved efficiency and safety in hydraulic and pneumatic systems. Learning how does a check valve work not only informs proper system management but also highlights the value of quality components like those offered by COVNA.

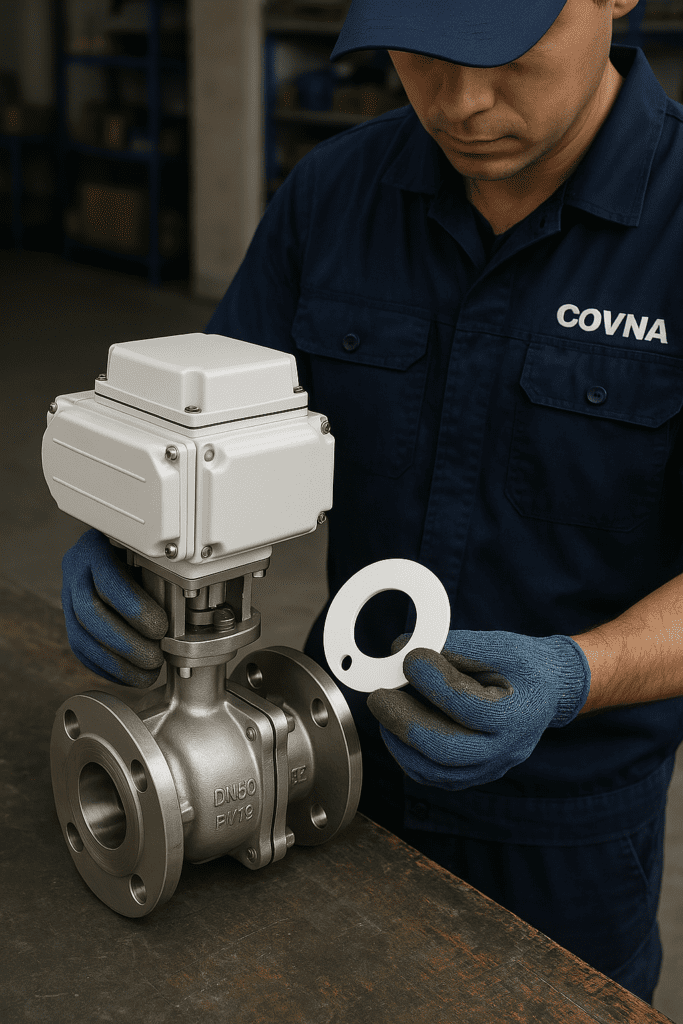

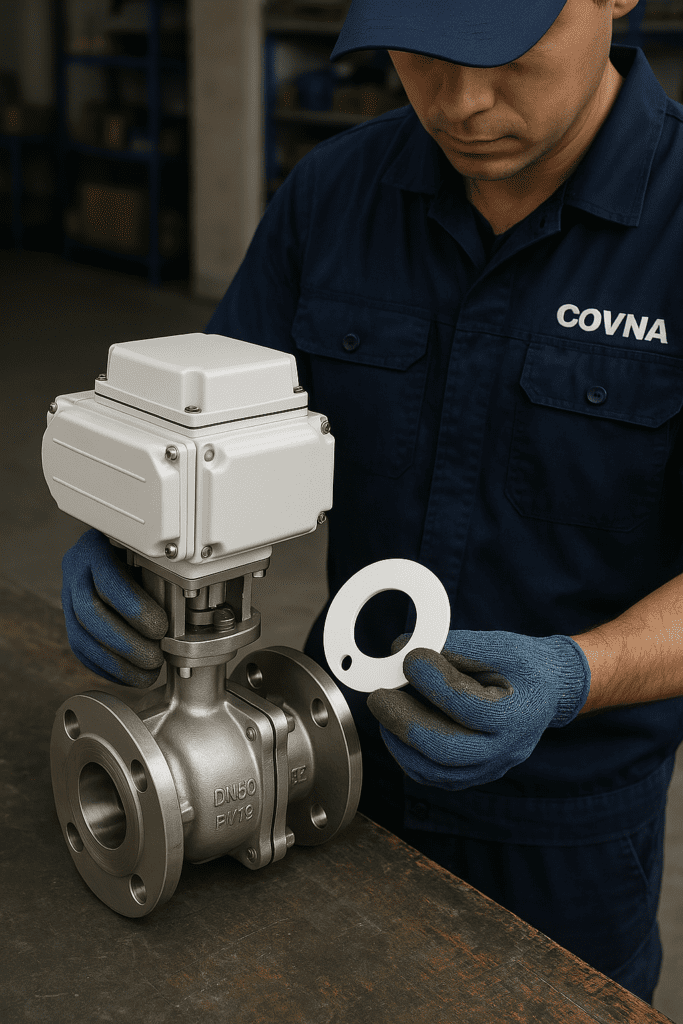

Knowing how to change valve cover gasket is essential for maintaining engine performance and preventing oil leaks. Over time, this gasket can wear out due to heat and pressure, leading to reduced efficiency. Here’s a step-by-step guide to replacing it, ensuring a secure seal with COVNA’s reliable gasket solutions.

- Preparation – Before starting, gather the necessary tools: a socket wrench, screwdriver, gasket sealant, and a new COVNA valve cover gasket.

- Disconnect Components – Remove any hoses or wiring obstructing the valve cover. Use a wrench to loosen and remove the bolts securing the cover.

- Remove Old Gasket – Carefully lift the valve cover and peel off the worn gasket. Clean the surface to ensure a proper fit for the new gasket.

- Install New COVNA Gasket – Position the new gasket in place, applying a thin layer of gasket sealant if necessary.

- Reattach Valve Cover – Secure the cover with bolts, tightening them evenly to prevent warping.

- Reconnect Components – Restore hoses and wiring, then start the engine to check for leaks.

Following this process ensures a proper seal, preventing oil leaks and maintaining optimal engine function with COVNA’s durable gasket solutions. Understanding how to change valve cover gasket helps extend the life of your vehicle.

When asking "what is a valve cover gasket," we are referring to a small yet essential component that seals the joint between the engine block and the valve cover. This gasket prevents oil leaks and keeps dirt and contaminants out of the engine, ensuring smooth and efficient functioning under high heat and pressure.

Manufactured with durability in mind, the valve cover gasket is a critical part of your engine’s overall performance. COVNA has built its reputation on providing high-quality gaskets that offer reliable protection and longevity. Their design improvements enhance the gasket’s ability to withstand constant temperature changes and mechanical stress, making it a trusted choice for both mechanics and car enthusiasts.

Choosing the right gasket, such as those from COVNA, is vital for maintaining engine performance and prolonging the life of your vehicle. Understanding what is a valve cover gasket and the role it plays can help you keep your engine in optimal condition without unwanted leaks or oil wastage.

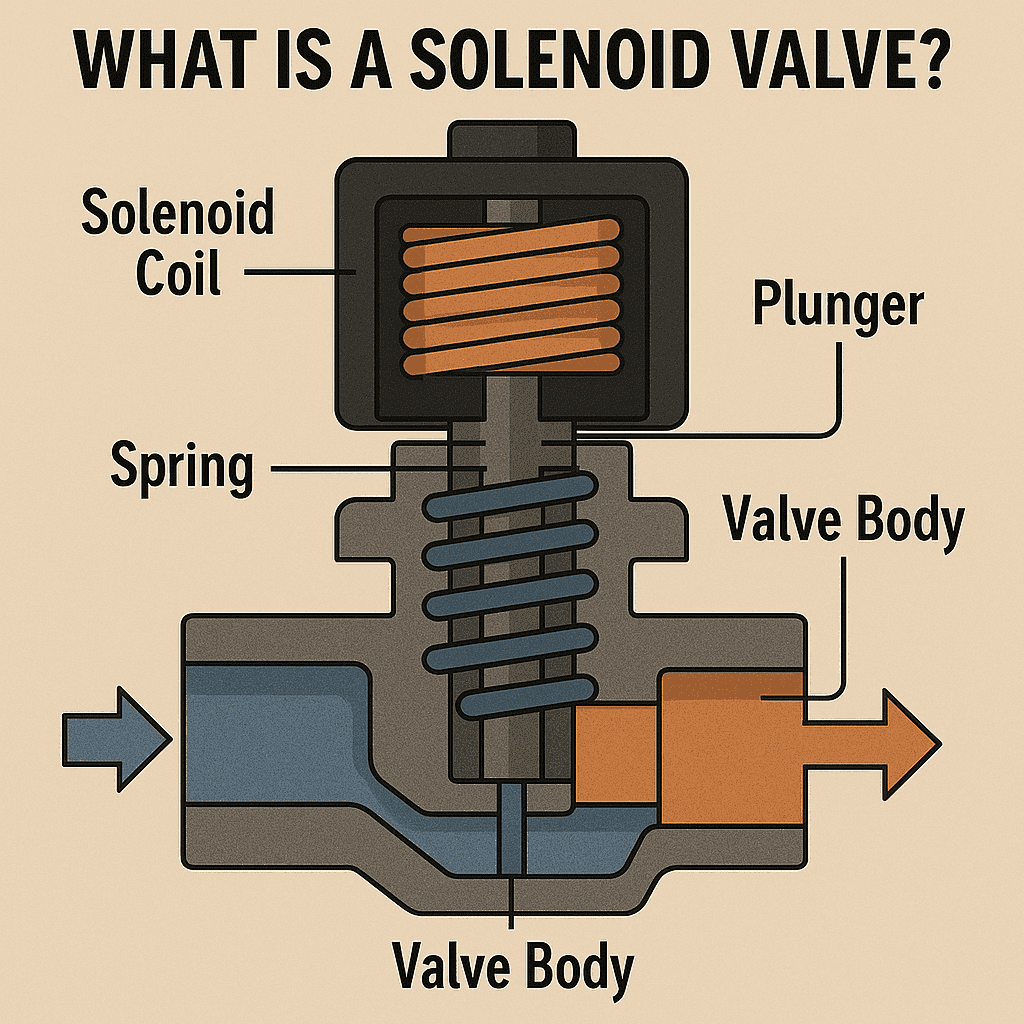

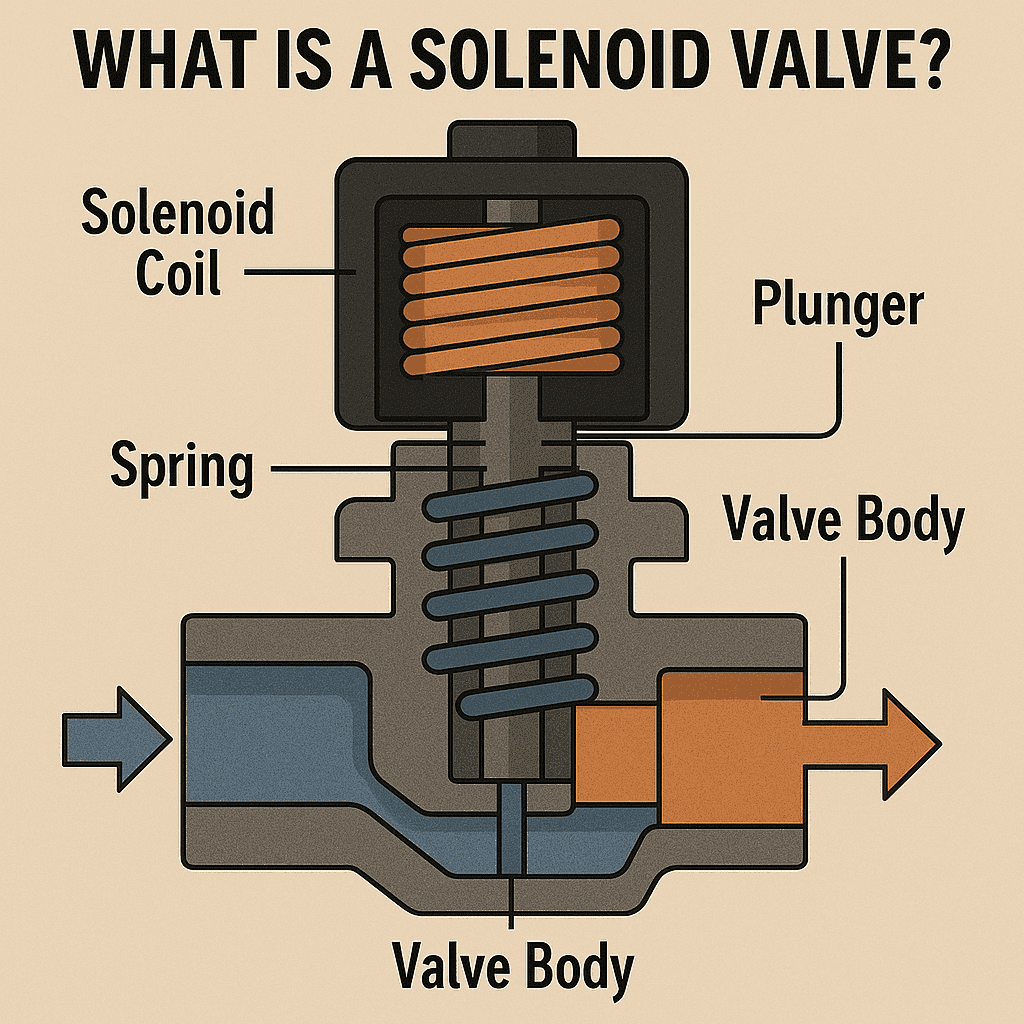

A solenoid valve is an electromechanical device designed to control the flow of fluids. It operates when an electric current energizes its coil, creating a magnetic field that moves a plunger or armature. This movement opens or closes a pathway, allowing water, gas, or other mediums to flow. Solenoid valves are widely used in industrial automation, irrigation systems, and heating and cooling applications because of their speed, reliability, and ease of control.

Leading the market in innovative designs, COVNA manufactures high-quality solenoid valves that excel in efficiency and durability. By incorporating advanced materials and rigorous testing, COVNA ensures that every valve meets industry standards and delivers precise control for complex systems. Their solutions have become essential for projects ranging from small-scale installations to large industrial processes.

Understanding the operation of a solenoid valve is key for anyone looking to optimize fluid management systems. Its simple design belies an impressive range of applications, making it a vital component in modern automation and control. Whether for personal projects or robust industrial systems, the dependable performance of solenoid valves continues to drive technological advancement.