Pneumatic Ball & Butterfly Valves: Types and Applications

Compact Pneumatic Control Valve with Manual Override

Compact pneumatic control valve features a manual override knob for testing or emergency operation. Brass body and 1″ G ports handle 0–8 bar. Quick-connect fittings allow tool-free installation. Ergonomic knob and flow scale provide ±3% repeatability. PTFE-packed spindle and electro-polished passages minimize wear and pressure drop. Snap-on mounting clip and captive bonnet screw enable easy maintenance in pneumatic panels and calibration rigs.

Pneumatic Valve Spring Compressor Maintenance Tool

Handheld spring compressor tool features a hardened steel frame and adjustable jaws for 5–50 mm springs. A ratcheting handle with quick-release lever speeds compression cycles, and a safety lock pin secures springs. Weighing 1.2 kg, it fits maintenance kits. Ideal for disassembling valve cartridges, replacing seals, and rebuilding actuator modules to reduce downtime and improve technician safety.

One-Way Pneumatic Exhaust Valve for Pressure Relief

One-way pneumatic exhaust valve vents air through a ¼″ port at up to 8 bar in a single direction. An anodized aluminum body houses a poppet and spring for automatic reset upon pressure reversal. Rated –10 °C to +60 °C. Its compact footprint suits safety interlocks, emergency stops, and rapid pneumatic venting in machine guarding systems.

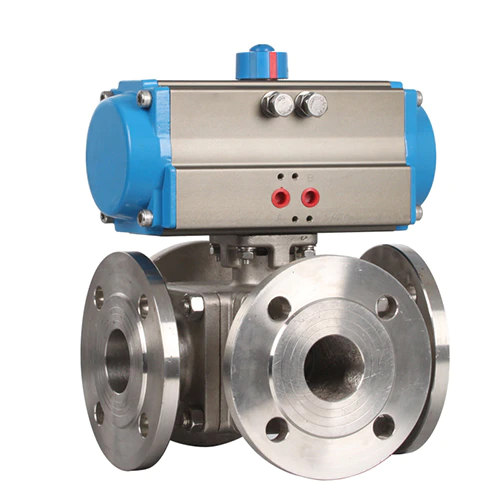

3-Way Pneumatic Ball Valve with Actuator, 250 PSI

3-way pneumatic T-port ball valve with SS316 body, Viton seats, and ½″ NPT ports, rated to 17 bar (250 PSI). Double-acting actuator accepts 4–8 bar and uses a spring return for fail-close. Precision ball and ports ensure smooth flow. ISO 5211 mount and visual indicator streamline installation. Ideal for mixing, diverting, or shut-off in chemical, food, and pharmaceutical systems.

We Have The Best Solutions for Your Business

COVNA GROUP CO., LTD is a world-leading valve manufacturer which specialized in solenoid valves, pneumatic valves, and electric valves for pipeline fluid control. COVNA originated from German technology, has its own R&D, design, production, sales team, and aims to be the global automation application service provider.

COVNA production range includes solenoid valves, pneumatic valves, electric valves, gate valves, globe valves, butterfly valves, control valves, safety valves, and various special valves. COVNA products are widely used in Water & Waste water treatment, Automation, Petroleum, Chemical, Electric power, Metallurgy, Mining, Paper-making, Pharmaceutical Industries, etc.

COVNA team make a rapid response to customer's requirements, provide professional product selection guidance and reliable valve application solutions.So far, COVNA has achieved ISO 9001 Quality Management System Certification, CE Certification, RoHS Certification.

Why Choose COVNA

Global Expertise

COVNA delivers valve solutions to customers in over 120 countries, combining global market expertise with localized support to meet diverse industry needs and ensure reliable performance worldwide.

Advanced Technology

Backed by German technology, COVNA specializes in solenoid, pneumatic, and electric valves, providing innovative fluid control solutions designed for precision, efficiency, and long-lasting durability.

Strong Manufacturing

With a modern factory, CNC machining, and strict quality testing, COVNA ensures every valve meets international standards, delivering consistent reliability for water, oil, gas, and automation industries.

Trusted Brand

Recognized as a preferred supplier by global partners, COVNA has built long-term trust through consistent product quality, professional technical support, and comprehensive after-sales services.

FREQUENTLY ASKED QUESTION

Do You Have Any Question?

A pneumatic valve is an actuator that uses compressed air to control the flow or direction of a fluid. Common types include solenoid valves, directional valves, flow control valves, check valves, pressure regulating valves, and actuators such as ball valves and butterfly valves.

First, determine the media type, rated pressure, temperature range, and required port diameter. Then, consider the coil voltage, response speed, and sealing material. Finally, consider the installation method and certification requirements.

Before installation, clean the piping and install a filter-pressure regulating unit. The interface between the actuator and the valve body should be centered, and bolts should be tightened evenly and symmetrically to avoid uneven loading. During commissioning, first test the air flow with no load, then gradually increase the pressure to the rated value. Check the travel, sealing, and return reliability.

Leakage: Check seals for wear and threads for tightness. Seizure: Clean the valve core, lubricate the guide, or replace the filter element. Coil inactivity: Measure voltage and check coil resistance. Slow actuation: Clean the air source, adjust the speed regulating valve, or replace the spring.

Regularly clean the air inlet filter and keep the lubrication unit filled with oil. Check joints, seals, and springs for wear. Verify air leakage every six months. Replace internal components promptly in case of severe contamination or wear to extend the life of the valve body and actuator.